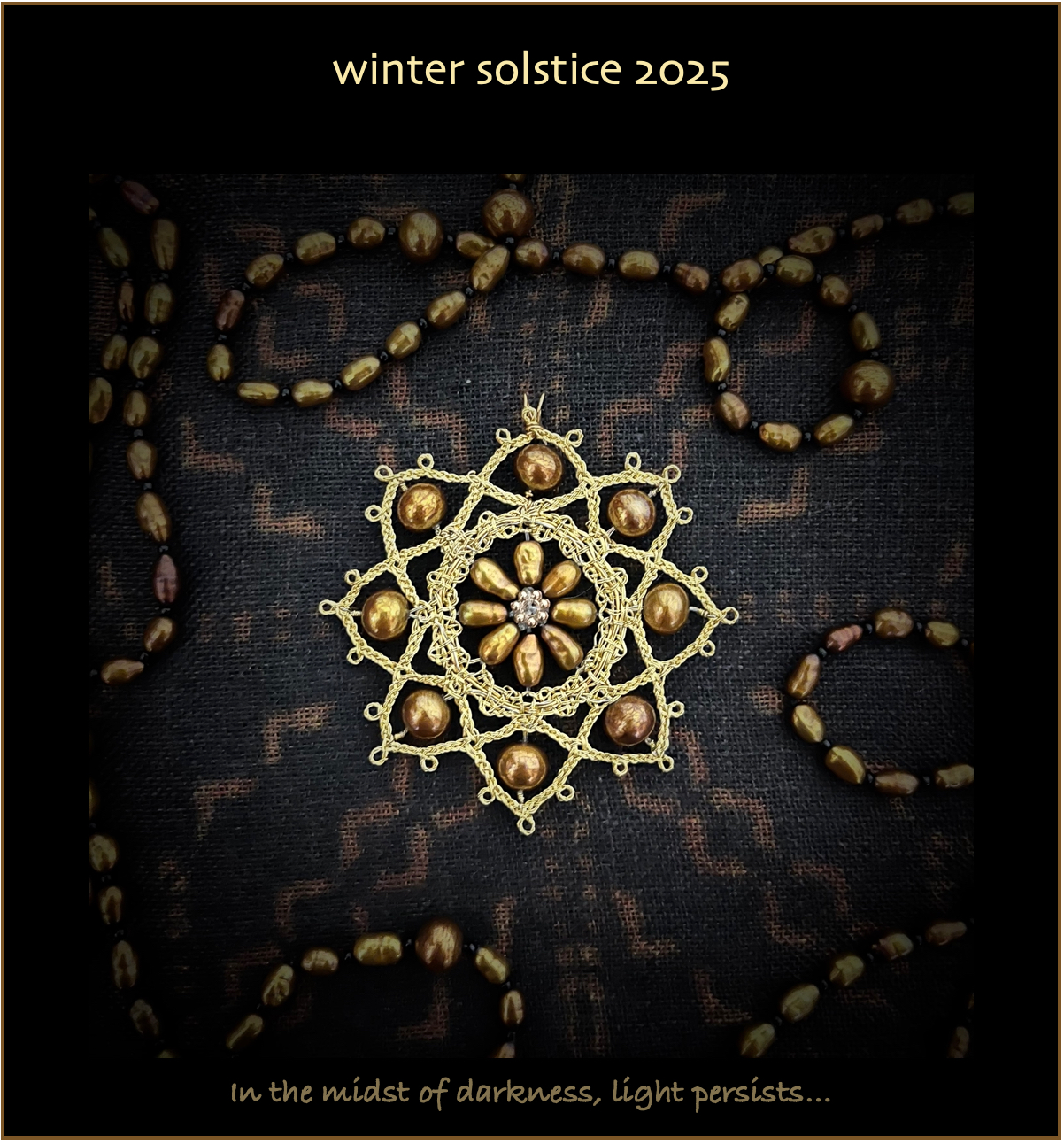

Winter Solstice 2025

Posted on December 21, 2025

May the long nights of winter inspire enough lace projects for the entire year!

Wishing everybody a happy and creative time,

Lenka

In photo above:

Plaited lace Star Pendant in gold plated copper with fresh water pearls

Category: Blog Tagged: gold plated copper, handmade bobbin lace, plaited lace, star, winter solstice, wire lace

Summer Solstice 2025

Posted on June 20, 2025

May the warm light of summer brighten our lacemaking pillows and illuminate all new lace projects!

Wishing everybody a happy and creative summer,

Lenka

Category: Blog Tagged: handmade bobbin lace, summer solstice, sun, wire lace

ARTS 2025 EXHIBITION

Posted on May 19, 2025

May 19, 2025

I am pleased to share good news that my work “Divine Harmony: Offering to Mother Earth and Father Sun” has been selected for a group show ARTS 2025.

As described by the organizers, Arts Council of Surrey and the Surrey Art Gallery : “This annual open-juried art exhibition celebrates art making throughout Surrey and beyond. Entries appear in a wide range of themes and media, from captivating landscape paintings to intricate sculptures and weavings. The artworks are displayed throughout Surrey Arts Centre, and visitors are invited to vote for the People’s Choice Award at any time during their visit.”

I participated in this show twice before (2018, 2020) and I am thankful that the organizers are still interested in presenting traditional art forms along the new media, which now also includes AI generated art. Surrey is truly multicultural city and ARTS 2025 exhibition brings together artists from around the world who now call Surrey their home. While the selected works offer a truly colourful mix of ideas and techniques, they all reveal their creators’ common enthusiasm for visual arts and dedication to the creative process.

To be able to participate with a piece made entirely by hand in a five hundred years old technique is rather remarkable in this day and age, and I will use the opportunity to popularize the bobbin lace art to the broad audience. In promotion materials the Divine Harmony is described as Mixed Media, probably due to need for brevity, so I hope for a chance to share more information about my work and bobbin lace technique in general at two related live events: Artist Open Mic on June 5th, or at the Summer Art Party on July 5th.

For those of you unable to visit the the gallery in person, you can see the work here: Divine Harmony

Also, you can watch a short documentary, produced for CBC Creator Network, about Colin Hamilton, an artist woodworker who made the frame for my lace:

“Ancient Craft, Modern Art : On the quiet shores of Pender Island, Colin Hamilton found his calling as a master of the ancient art form of woodworking. Watch as this Canadian artist transforms raw lumber into works of art…”

After years of neglect, the Canadian arts and crafts are finally getting some attention…and that is welcome news indeed!

Please share with your friends and support local arts this spring and summer!

Lenka

Category: Blog Tagged: ARTS 2025, bobbin lace, divine harmony, exhibition, handmade lace art, lace sculpture, Surrey Art Gallery, wire lace

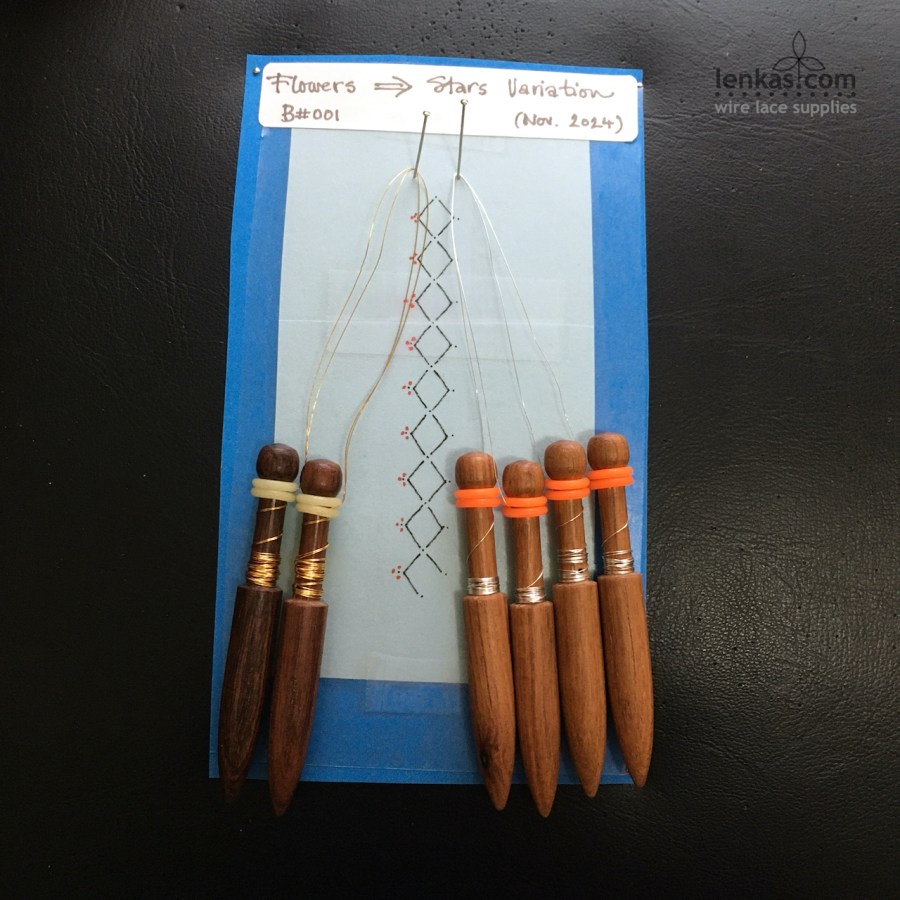

Turn Your Flowers into Stars

Posted on November 25, 2024

November 25, 2024

The only flowers left in my yard are lovely and hardy Calendulas, and as the temperature is falling bit by bit every day, even they will be gone soon. In summertime I found so much pleasure in observing and caring for flora around me and now time has come for good rest. I am looking forward to long winter nights to turn my gaze up to the stars. Heavenly contemplation always fills me with wonder and deep gratitude… and lots of creative ideas.

Let’s muse on… how about turning the Flowers into Stars?

It’s easy. With a few simple modifications the Flower Earrings Pattern will produce delicate stars.

All what we need is a couple meters of shiny wires, a dash of sparkling beads, six bobbins and a pillow, and a quiet afternoon. By twilight, our first stars will be ready to shine!

Here is how:

1. Extend the pricking

Print two copies of a pricking A (page 3), and cut and paste them together to get nine repeats of the pattern. The original flower pricking had six repeats and we are adding three more.

2. Add extra dots on pricking for triple picot

As opposed to flower design, the star has three picots at the tips, so it can shine and radiate light. Add three dots evenly around the original single picot dot.

3. Change quantity of bobbins

To simplify things and also to make the centre of the future star stronger, two pairs of single-wound bobbins will be replaced by one double-wound pair. So instead of four equal pairs we will work with just three:

– 2 pairs with single wire, 40cm on each bobbin (about 16”)

– 1 pair with double wire, 40cm on each bobbin (about 16”)

All together, there are the same number of wires (8), distributed differently on three pairs instead of four. For clarity, I used two different colours in the sample, silver for single wire pairs and gold for double wire pair. But of course, they can all be the same colour.

4. To finish the star, smaller seed beads are needed – size 10/0 or 11/0 or 15/0 – and one large bead for the centre of the star – 4 or 6mm round or faceted bi-cone.

Let’s start working:

Keep the Flower Earring Pattern on hand for reference.

1. Hang a double pair on left support pin and two single pairs on right support pin, one on top of the other.

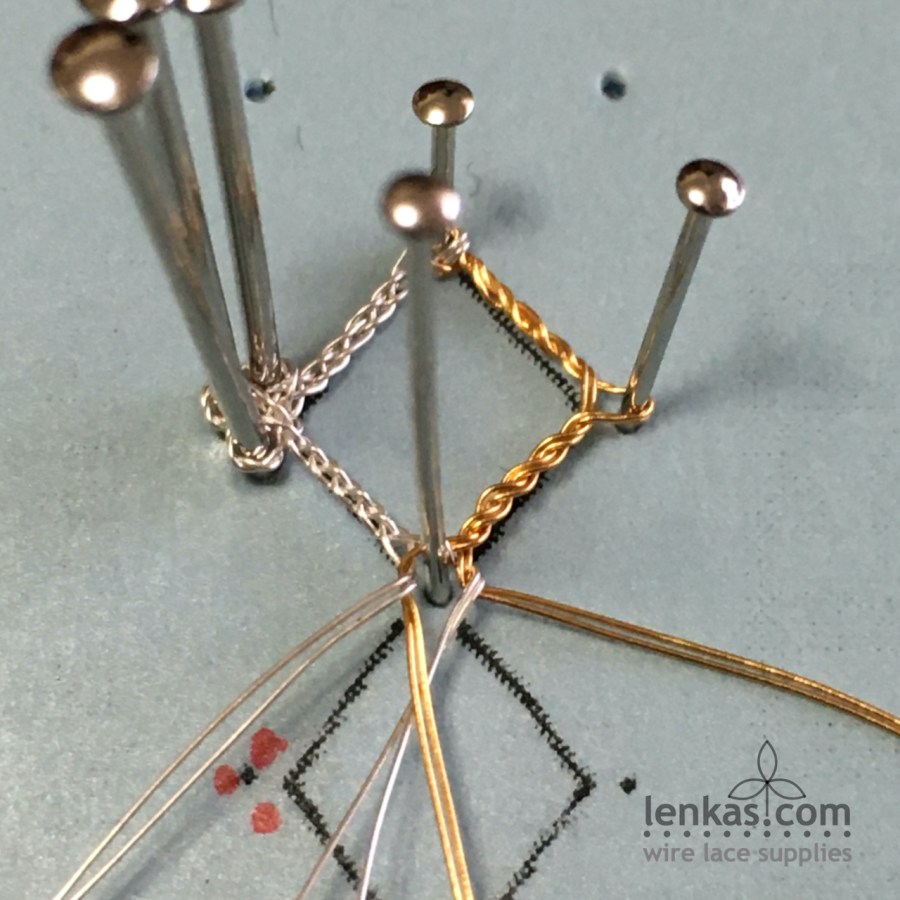

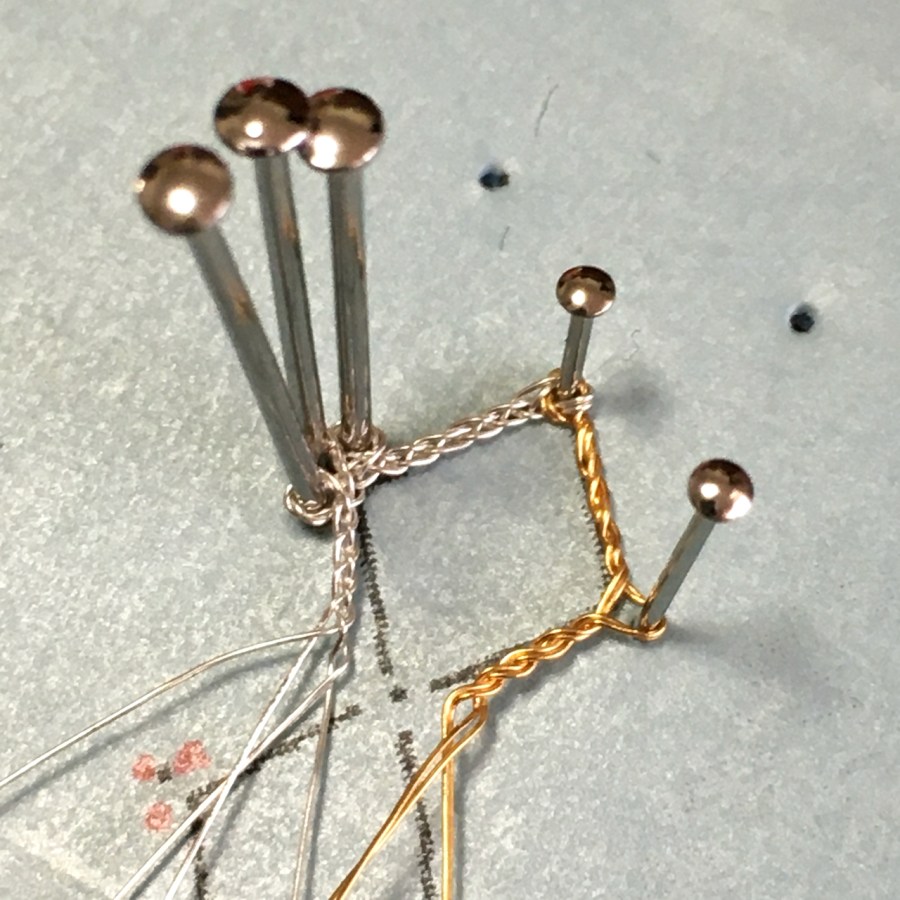

2. Work a regular windmill (see page 7). It will be a little bit easier, because the gold wires are wound only on one pair. Stitch steps are the same: Cross-Twist-pin-Cross-tension.

3. After the windmill, work with the gold double pair on right side, Twist and tension firmly, then repeat five more times to get six twists in total. Lots of twist for a short distance, but with firm tensioning you should be able to fit them all in. If it’s a struggle, just five twists will do, but six of them give stronger support. Place pin. Twist-tension six times.

4. On the headside, work a braid with two pairs, then make a triple picot. Triple picot is made of three regular picots, separated by a cloth stitch. Make the first picot, either scooped or wrapped (see page 11-12), C-T-C-tension, make the second picot, C-T-C-tension, make third picot, C-T-C-tension and continue with the braid towards the next windmill crossing.

5. This windmill crossing and all remaining ones in the pattern are worked as Windmill with a Twist (see page 9 for full explanation). Cross-Twist-pin-Twist-tension-Cross-tension. The extra twist in the middle of crossing will keep the single (silver) pairs on the headside and the double (gold) pair on the footside.

Keep repeating the steps until the end of pattern.

Beading and finishing is the same as the Flower (see page 17, and page 23).

A tip for finishing two coloured star:

Connecting the end and start points to complete the circle is done with two outer pairs, which are then braided towards the centre. It means that this last braid will be a “wrong” colour (silver in the sample). To cover that irregularity, use one of the gold wires, lead it towards the start/end windmill, thread the wire through the crossing to secure it there, and then wrap the wire tightly around the silver braid, all the way to the centre of the star. It’s a fiddly job, but worth the effort if you want your star earrings to be perfect.

The star’s final shape will be determined by the size of seed beads in the centre – smaller beads make the centre tighter, while use of bigger seed beads leads to a larger opening. Choose a focal bead that fits in the middle – round or bi-cone faceted crystals in size 4-6mm work well, because they give a nice, sparkly accent to the star. The centre bead also provides ample hiding space for the wire ends, since the seed beads in sizes 10-15/0 are too small to contain all of them.

Add a finishing touch to the star by gently squeezing the braids together under the windmill crossings and triple picots. It will make the rays look sharper and neater.

Have fun, play with wires and beads, and make a lot of stars to illuminate the path during winter months. Find ways to distribute them far and wide – on greeting cards, special gift tags or festive ornaments. They are small and delicate, but being handmade, they radiate love and light as if by magic.

If you don’t have the Flower Earrings Pattern & Tutorial yet you might be pleased to know that during Wire Lace Supplies Christmas Sale, from November 26 to December 26, 2024, there is 20% discount on all patterns. Go ahead and give the Flower/Star a try!

Happy lacemaking and star making,

Lenka

Category: Blog, Uncategorized Tagged: bobbin lace, flower earrings, lenkas lace, pattern, star, tutorial, wire lace

Serendipitous Wire Test

Posted on November 19, 2024

November 19, 2024

I like to say that wire lace is forever. It is true, because wire is much stronger than threads and deteriorates slowly. But when some of my metal lace creation changed colour over time I realized that longevity of wire coating might be uncertain.

Craft copper wire is coated with a layer of material that protects the raw metal and gives wire its colour. When the coating is not completely sealed the air reaches wire beneath and reacts with it in a natural chemical process. In case of outside copper and bronze sculptures, it is expected and accepted that the tarnish will eventually deposit and permanently colour the artwork. But it is much harder to surrender our delicate lace art to natural forces. We know what happened to antique metallic laces when they lost their lustre…

The first copper wires I used for making lace were from magnet coils found in old electrical appliances. They were durable, made to withstand harsh conditions of various environments. Despite being fifty-sixty years old the spools of wire looked like new. Old enamelled wires were of excellent quality, made to last, but the choice of colours was limited. Many of my works were created in the typical colour range of reds, yellows and browns, with occasionally green. It was fine at the beginning, when I welcomed any wire for my lace, but then of course I started to dream about blues, turquoise and purples…

Luckily, I was not alone searching for coloured copper. There was a growing demand from other artisans and artists – knitters, weavers and crochetiers (and zealous fly tyers). Right at that time some manufacturers, looking to find alternative markets, started to produce wire for craft field. It was not an easy task to satisfy the needs of creative people who wanted soft, pliable wire in lots of colours. New products were tested with mixed outcomes. The coating was posing the biggest challenge; often it was weak and chipped or peeled off during work. Sometimes the wires worked fine, but the colours were unstable and turned dull and grey really quickly. It was time of trial and error but finally a handful of manufacturers were able to produce reasonably stable coloured copper wire. I still have some works from those times, still in good condition, aging gracefully as their colours are slowly fading. And now, many years later, I have a better understanding of the process.

Eventually, I found good quality wires for lacemaking, and I consider myself lucky to be able to work with material that is worthy of such time-consuming and labour-intensive craft as bobbin lace. Over time, “my” manufacturer produced many beautiful colours while keeping or exceeding the quality standard.

About two years ago, I noticed the wire changed. Being too small a customer, I do not get informed about product modifications, but I could see and feel the difference in the new spools. The colours were richer and brighter and the wire felt just a tiny bit harder, springier. Based on my experience, I deduced that the coating technique changed to produce brighter hues, and I trusted that the surface quality improved as well. I tried a few simple chemical tests with satisfactory results, and left it at that. Time will tell.

And soon enough, it did. This year, when I was working in my front yard, trimming back a pachysandra border, I noticed bright sparkle in the depth of the bundled stems. I reached in and pulled out two spools of wire, silver plated and bright pink colour. They looked like they have been there for a while, because the spools were all dirty. and wet. But the colours were still brilliant!

How did the copper wire spools end up in the vegetation?

With each new product I need photos for my online shop. Because the shiny wires are difficult to photograph in artificial light, I have the best chance to capture true-to-colour images in muted natural daylight on a cloudy day. So I usually set up the photo station on a landing in front of the house. After a photoshoot on one of those perfect grey days, two runaway spools did not make it back home. They must have slipped over the edge of the landing and descended into pachysandra’s embrace. I did not notice them missing and they stayed there… for a very long time. The wire was exposed to outside elements – a lot of moisture during rainy season, followed by dry summer heat (but not direct sunlight), steady ocean air breeze, rain again, and cold, including extreme freeze (for the West Coast of Canada anyway) of minus fifteen degrees Celsius for almost a week. Even the pachysandra, a tough plant that normally tolerates our weather without complaining, showed some frost damage after the winter.

Surprisingly, the two spools of enamelled copper wire survived intact. I cleaned them and they look like new. A very impressive result of the unplanned test, and a proof that the quality of these wires is indeed excellent! Their coating’s ability to protect the colour is especially significant in the case of the silver plated wire. Silver readily tarnishes when exposed to moisture, and would turn black quickly if the surface was not perfectly sealed.

Now I have a proof that the silver-plated copper wire is truly non-tarnishing! And I am very happy to know that with this material our wire laceworks have a real chance to be forever 🙂

Remember to treat the wire gently to keep the surface whole and prevent scratches by pins, sewing hooks and nudge tools. With proper care your wire lace will shine and sparkle for years to come.

Both lost and found spools are now back in my studio. I will not sell them, of course, they stay in my wire box for future observation. They join other spools in my collection of miss-shaped, mislabeled and miss-wound spools. Eventually the wire will complete its uncommon journey and become a piece of unique lace.

Just in time for a merry crafting season, WireLaceSupplies shop is stocked with wire in every colour for all your creative needs 🙂

Happy lacemaking, and lacemaking with wire especially!

Lenka

PS: Before I finished writing this post, I already started working on a new project with the mentioned silver wire. Next post is coming soon!

Category: Blog Tagged: handmade bobbin lace, silver-plated copper wire, wire lace, wire lace supplies

Sun Time!

Posted on June 21, 2023

Summer is so good for lacemaking in Canada.

We have extra long days (16 hours,12 minutes and 27 seconds on solstice today), which means a plenty of natural light that is really best for fine hand work. And because our summer arrives after a long harsh winter, it brings so much joy and positive energy that it almost feels like a spiritual experience. Like reconnecting with the Life Source, rejoicing in its presence and and reposing in its embrace.

In my studio, the Spring Blossoms are gone, and the workspace is ready for the next project.

I am thinking about a Renaissance Sun, like many I made before, but bigger and stronger, able to rejuvenate the nature and breathe new life into everything, and art in particular.

Because we really need it now.

I wish to myself – and every creative person out there – a heavenly inspiration, calm mind, steady hands and a plenty of time for all summer projects!

Category: Blog Tagged: cherry blossom, jewellery, needle lace, pendant, sun, wire lace

Spring Equinox 2023

Posted on March 20, 2023

Category: Blog Tagged: cherry blossom, jewellery, needle lace, pendant, spring equinox, wire lace

Old Wise Tree Gallery

Posted on May 25, 2021

The long-awaited gallery is now online.

Please visit and enjoy a virtual stroll in a park with spectacular display of handmade lace trees.

Old Wise Tree Gallery

Category: Blog Tagged: bobbin lace art, fibre lace, gallery, old wise tree, wire lace

Free Old Wise Tree PATTERN/TUTORIAL

Posted on January 16, 2021

The first new moon of the new year has been born in the midst of darkness to mark a new beginning. Days are getting longer in the Northern Hemisphere, which means that the solar system is still in sync, and we are safe to make plans for the months ahead.

With an obvious bias I say: “Let’s make a lot of lace this year!” And I really mean it.

The virtual world that is a part of our present experience is bewitching as it flounders in a perpetual chaos. But the real world, and real everyday life benefits from at least some order. Handmade lace craft inherently contains that harmony. I believe that throughout the centuries, lacemakers were finding tremendous satisfaction in transforming a multitude of loose threads into symmetrical patterns. And today is no different.

In our times of exaggerated efficiency, it may seem useless, or even wasteful and selfish to spend hours at the lacemaking pillow, with no other purpose than to enjoy peaceful, slow, ‘unplugged’ activity. But if you have ever experienced the inner peace achieved through the handwork, and noticed how that tranquility fills the surrounding space and transfers to the lace itself, you know better.

You know that the true purpose and true fulfilment in life comes from within.

To contribute to a good start of the New Lace Year 2021, I am offering a free Old Wise Tree Pattern and Tutorial to all lacemakers who are looking for a new creative project. The pattern is suitable for fibre or wire lace, and it would be great if it inspires lacemakers to work in both mediums.

The comprehensive tutorial includes step-by-step instructions with detailed photographs of the whole work, from preparations to mounting the lace to the background. The Old Wise Tree Gallery is coming soon to showcase the unique lace trees, and you can add yours too, if you wish to share it.

Enjoy, explore and create!

And keep in mind, that the fine balance of this world might as well be in lacemakers’ hands 😉

Category: Blog Tagged: bobbin lace, free pattern, handmade lace art, old wise tree, wire lace

Free Trial Pattern for Wire Lace

Posted on June 2, 2020

Give wire lace a try in this easy excercise!

Handmade bobbin lace keeps evolving, and many contemporary lacemakers and lace artist use non-traditional materials, such as metal. In the last twenty years wire lace has gained considerable popularity, and more and more lacemakers are attracted to it.

Lacemakers who work with fibre are often curious about working with wire: How difficult is it? Can anybody do it? Are the special tolls really necessary?

Based on my experience of making lace with metal for more than 30 years and teaching wire lace techniques to others for almost as long, my answer is always affirmative: “Yes, you can do it!” and “Yes, it is better to have the right tools and materials for the best results”.

In the simple manual “Wire Lacework – Lenka’s Introduction to Bobbin Lace in Wire” written with an aim of helping lacemakers with the transition from fibre to wire lace, I explained the basic differences between tools and materials. A series of basic patterns for wire lace followed, each dedicated to a particular technique in full detail. These publications are available for purchase in my Wire Lace Supplies shop on Etsy, and many lacemakers have downloaded them already. Special bobbins for wire lace, together with colourful wires, are popular as well, and I am happy to supply them to lacemakers around the world to help make the wire lacework accessible to all.

But what about those who are not sure if they will like the medium? Or can’t justify investing in a new set of bobbins yet? For those of you, the new Trial Pattern for Wire Lace Newbies is here to help.

You can try making wire lace with the tools you already have and test the new medium in this simple trial pattern.

You will need:

- 6 pairs or regular lacemaking bobbins that you use for fibre lace

- copper wire

- old scissors for cutting wire

- lacemaking pillow (any style)

- pins

- materials for preparing the pricking (same as for fibre lace)

Let’s start from the beginning, with the most important points first:

1) Attitude

Approach this project as a playful excercise, and not as a serious assignment (rather like a first date, as opposed to a wedding day). Do not set any expectations and keep your mind open to the new experience. Wire is different than thread and it needs different handling. The best way to discover its qualities is to go slowly and pay close attention wire’s behaviour. Allow the wire to show you the way and follow gently. You know the stitches, and wire knows its own preferences. When you work together, you will make a fine team.

2) Wire

Make sure that you have the right wire. This is absolutely essential. Unsuitable material can turn you off wire lace forever, and that would be a real shame. I recommend copper wire in sizes 0.2mm – 0.25mm (in American Wire Gauges #30-32). Good quality copper wire should be soft and pliable to accommodate the stitches. Stay away from brass and aluminum and from wires with unknown content. While it is possible to work with those wires (later, when you have more experience), your first wire lace should be attempted with the most compatible wire, and that is a pure copper wire.

You can make a simple test of the wire pliability: cut a piece of wire and tie a basic bow with it. If you are able to work with the wire easily, and the knot can be tied almost as tightly as with a thread, the wire is suitable for lacework. If the wire feels stiff and the knot doesn’t close, the wire is not acceptable, because it has too much resistance to conform to the stitches.

Red bow – unknown content, coated – too thick and rigid – not suitable for wire lace

Purple bow – pure copper 0.2mm (AWG 32) – perfect for wire lace If your wire is not up to the standard, do yourself a favour and postpone the wire lace trial until you have the right material.

If your wire is not up to the standard, do yourself a favour and postpone the wire lace trial until you have the right material.

3) Lacemaking pillow

Any pillow will work for this pattern. I used a student pillow, that has been serving to beginners in my studio (and many of my own projects in between) for the last 5 years (and is still good to use!) 4) Pins

4) Pins

Generic dressmakers pins are better than fine lacemaking pins. In the sample, extra long dressmakers pins were used, and extra thick pins for picots.

5) Bobbins

Use the bobbins you would utilize for making lace with linen #40/2, which are generally bigger, thicker and heavier than those for fine lace. I used traditional Belgian Torchon bobbins that I recommend for students who are learning fibre lace basics.

It is important that the bobbins are not empty, but wound with thread. Leftovers from the past project are ideal. The threads will help to anchor wire, so it won’t be slipping and unwinding from the end.

PREPARATION:

Bobbin winding

Prepare 6 pairs:

0.9 meter (3ft) per bobbin [1.8m (6ft) total wire length for one pair, divided equally between 2 bobbins]

Match the fibre and wire end and tie them together with a simple knot.  Start winding the wire at the lower part of the neck, wrapping several turns over the ends. This should bury the knot in the layers of fibre underneath, and hide the sharp wire end.

Start winding the wire at the lower part of the neck, wrapping several turns over the ends. This should bury the knot in the layers of fibre underneath, and hide the sharp wire end.

Work slowly and watch the wire. Keep it open and free at all times to prevent kinks or snags. Observe your good habits from fibre lace and add wire by the means of turning the bobbin (as opposed to wrapping the wire around bobbin). Layer the wire rows over the thread, not too tightly, but not too loosely either. Secure the wire with a half hitch. This one loop is enough to hold the wire on the bobbin and is easy to release.

Work slowly and watch the wire. Keep it open and free at all times to prevent kinks or snags. Observe your good habits from fibre lace and add wire by the means of turning the bobbin (as opposed to wrapping the wire around bobbin). Layer the wire rows over the thread, not too tightly, but not too loosely either. Secure the wire with a half hitch. This one loop is enough to hold the wire on the bobbin and is easy to release. Pricking

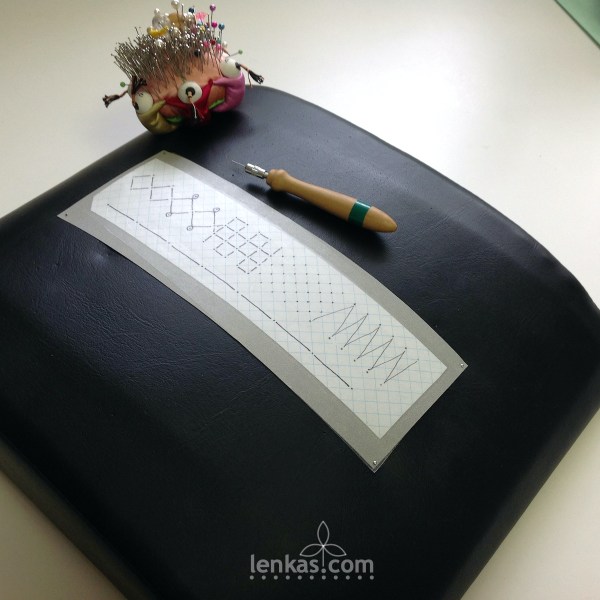

Pricking

Using a squared paper: imperial 1/4 inch (metric 6x6mm or 5x5mm), draft the pattern as in the picture.  Alternatively, print the pricking from the Free Trial Pattern for Wire Lace Newbies pdf file

Alternatively, print the pricking from the Free Trial Pattern for Wire Lace Newbies pdf file

Make sure that your printer is set to 100% to print the correct size (size check is included next to the pricking).

Prepare the pricking as you would for traditional fibre lace. If your pillow is on softer side, use a bit heavier card stock for backing. It will help anchor the pins to withstand firm tensioning.

Prepare the pricking as you would for traditional fibre lace. If your pillow is on softer side, use a bit heavier card stock for backing. It will help anchor the pins to withstand firm tensioning.

WORKING INSTRUCTIONS:

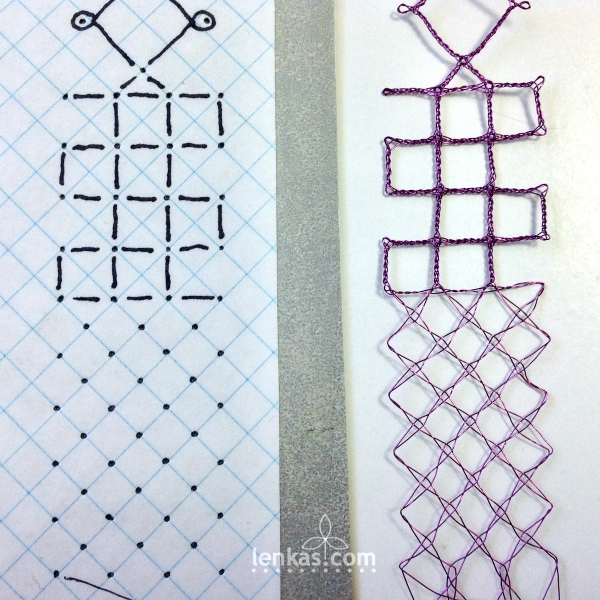

Plaits

Hang 2 pairs on the vertical line’s top pin.

Keep the “leashes” short – wire length from the pin to bobbin’s head should not be more than one length of the bobbin. Work simple plait: *start with linen stitch (cloth stitch) C-T-C and tension. Continue braiding T-C-tension, T-C-tension, … until the pinhole is reached. Pin between the pairs.** Repeat from * to **

. Work slowly and concentrate on tensioning both pairs well after each Cross. Feel the wire and learn how much to pull in order to tension the plait well. Continue working until the braid is nice and even. Compared to fibre lace, the plait made from wire should be textured and three-dimensional.

Work slowly and concentrate on tensioning both pairs well after each Cross. Feel the wire and learn how much to pull in order to tension the plait well. Continue working until the braid is nice and even. Compared to fibre lace, the plait made from wire should be textured and three-dimensional. Unpin the plait and move it to the pillow side. Use another 2 pairs and repeat the plait work.

Unpin the plait and move it to the pillow side. Use another 2 pairs and repeat the plait work. Windmill Crossings and Picots

Windmill Crossings and Picots

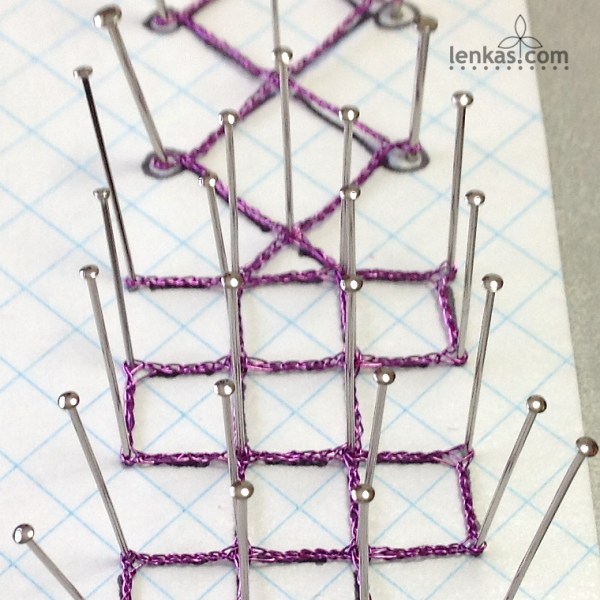

Pin both plaits above the pricking so they are ready to start working at the top of the main pattern. At the first pin, 4 pairs start with windmill crossing. With each pair working as one bobbin make C-T-pin-C, tension.

At the first pin, 4 pairs start with windmill crossing. With each pair working as one bobbin make C-T-pin-C, tension. After the windmill, two left pairs start with a linen stitch (C-T-C), and continue to plait (T-C-tension, T-C-t,…) towards left pinhole, pin between the pairs. Start the next plait towards the centre pin. When done, work with two right pairs in the same way (plait, pin, plait).

After the windmill, two left pairs start with a linen stitch (C-T-C), and continue to plait (T-C-tension, T-C-t,…) towards left pinhole, pin between the pairs. Start the next plait towards the centre pin. When done, work with two right pairs in the same way (plait, pin, plait).

. Make windmill crossing in the centre. Repeat.

. Make windmill crossing in the centre. Repeat.

In the 3rd diamond, add picot on the footside. Simple wrapped picot is easy: twist outside pair 3 times (tension after each twist: T-tension, T-tension, T-tension), wrap the twisted pair around the picot pin (clockwise movement on left footside, counterclockwise on right footside). Tension the picot well and start the outgoing plait with C-T-C.

When 4 diamonds are finished, take a short break: If you reached this point without encountering a major frustration, congratulations! That is a promising start. Reflect on your experience and let the new skills sink in.

If you feel that you could do better with more practice, unpin your lace, move it up and repeat 2 or 3 diamonds. When you are ready, proceed to the next part – plaited square grid.

Before you start, have a look at your bobbins – some wires might be short, some longer. Depending on your tensioning technique, sometimes wire gets released when the bobbin is pulled, and other times the pull actually tightens and locks the hitch. That is the nature of the half hitch, and the only remedy is to patiently adjust the lengths of the leashes by undoing the hitch and releasing wire if it is short, or re-winding if it is too long. When your bobbins are all adjusted to the same length, it’s time to proceed to the next segment of the pattern.

Plaited Square Grid

On the left side of the pricking, add 2 remaining pairs. Make a plait towards the next pin, work windmill crossing, plait, windmill crossing, plait, pin between pairs at the right edge pin. Continue working the grid. The intervals between the pins are identical, so each plait is the same length. It is helpful here to count number of plait stitches and repeat them in each segment to achieve uniformity of the braid. In the sample, I worked C-T-C to start the plait and then repeated T-C-tension 4 times (altogether 6 Crosses between the pins). In the last row of squares, I tensioned more and was able to squeeze one more T-C, to the total of 7 Crosses between the pins. See what you can do. Bear in mind that tensioning depends on the material. Every wire is slightly different, some are softer and therefore easier to tension, some are harder, and no matter how well you tension, minute gaps in the braid remain. That is fine, as long as the plait is nice and even. Before the last grid row (from left to right) leave the left plait pair behind, and finish the row with only the right pair: Twist the pair 3 times, work 3 pair windmill crossing, 3xT, 3-pair windmill crossing, pin under the pair at the edge pin hole. This distributes the pairs for the next segment: Torchon Ground.

Before the last grid row (from left to right) leave the left plait pair behind, and finish the row with only the right pair: Twist the pair 3 times, work 3 pair windmill crossing, 3xT, 3-pair windmill crossing, pin under the pair at the edge pin hole. This distributes the pairs for the next segment: Torchon Ground. Torchon Ground

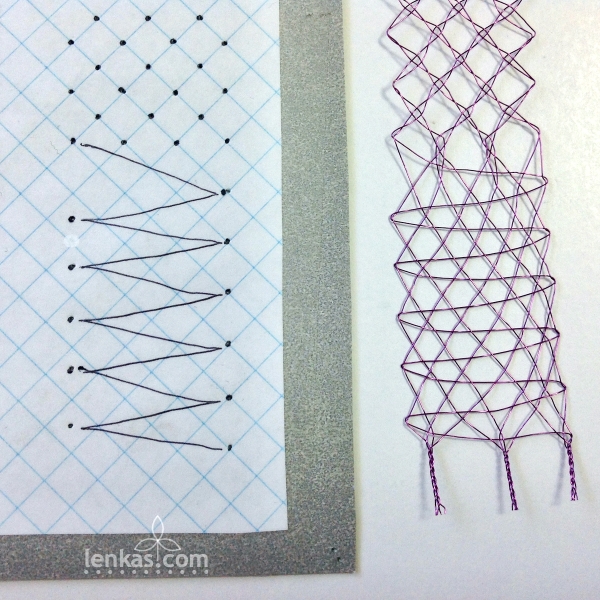

Torchon Ground

Torchon ground is easy to work and tension.The ground is done the same way as in fibre by following diagonal lines: C-T-pin-C-T-tension. Make sure to tension after each stitch. Once the wire is formed, it is hard to change its shape. Pulling on the diagonal pair at the end of the row, routinely used in fibre lace, is not very effective in wire medium.  Because wire keeps its shape so well, it does not require continual support of pins. It is therefore possible to start reusing pins from the top rows now.

Because wire keeps its shape so well, it does not require continual support of pins. It is therefore possible to start reusing pins from the top rows now. Half Stitch

Half Stitch

The last part of this trial pattern is a half stitch weave. First row starts on the left, worker makes half stitch C-T with each passive pair. Tension the worker well at the end of the row. Pin, add one Twist to worker, tension. If the single worker line sags instead of being straight, undo the extra twist and re-tension every passive pair (starting from the beginning of the row, all the way to the last passive pair). Then re-tension the worker, add 1 extra twist to it (to the total of two twists). Continue with half stitch weave.

After the last row, plait the neighbouring pairs to create 3 tails. Cut off bobbins.

Unpin gently and admire your first wire lace 🙂

Results

A) If you enjoyed this excercise and are happy with the results, it means that you have a natural talent for wire lace. With what you learned already, you can start exploring other designs – more complex plaited lace or Torchon ground patterns. At the beginning, avoid patterns with cloth stitch. While easy to make in fibre, cloth stitch requires more experience in wire lace, and therefore it is better left for later.

B) If you had fun doing this excercise, but are not wholly satisfied with the outcome, try to work the pattern again and concentrate on the points which need improvement. Since you already know the stitches, it will be easier to pay more attention to the technique, and the outcome will be more competent.

C) If you did not have fun at all and are not thrilled with your first wire lace sample, it might mean that wire lace is not for you, and that is OK, too. You tried and now you know. There are many laces to choose from and lacemakers have to select wisely to which projects they will dedicate their time and effort. You can share your experience with your lace friends and tell them about the Trial Pattern for Newbies, so they can make their own wire lace sampler.

I hope that this Trial Pattern for Wire Lace Newbies encourages more lacemakers to give wire lace a try!

If you have any questions regarding this project or wire lace in general, feel free to ask using the LEAVE A REPLY box below.

Additional Information

To learn more about techniques used in this tutorial, the Flower Earrings Pattern and Tutorial (Basics #001) offers more information about plaits and windmills. Half Stitch Leaf Pattern and Tutorial (Basics #002) is dedicated to mastering half stitch weave, and also explains how to mix colours with doubled wires.

Lenka’s Wire Lace Bobbins

The more wire lace you make, the more you will understand why dedicated wire lace bobbins are beneficial. They are designed to anchor the wire ends securely, and to hold and release wire gently and quickly. Having thicker necks, the bobbins prevent excessive curling (and therefore hardening) of the material, which results in happier wire and consecutively, a happier lacemaker. Medium bobbins for wire lace are extremely easy to use, and they are suitable for many styles of wire lace and many sizes of projects. On top of it, they work equally well for metallic threads. In my humble opinion, they would enhance every lacemaker’s toolbox 🙂

Lenka’s Medium Bobbins for Wire Lace are available exclusively in my Wire Lace Supply online store, currently hosted on Etsy.

Medium bobbins for wire lace are extremely easy to use, and they are suitable for many styles of wire lace and many sizes of projects. On top of it, they work equally well for metallic threads.

In my humble opinion, they would enhance every lacemaker’s toolbox 🙂

Happy lacemaking,

Lenka

Category: Blog Tagged: beginners, bobbin lace, free pattern, trial pattern for newbies, wire lace

Lenka's Way of Lace

Lenka's Way of Lace